Reliable Tahoe Instrument Cluster Repair: Obtain Your Gauges Functioning Once More

Reliable Tahoe Instrument Cluster Repair: Obtain Your Gauges Functioning Once More

Blog Article

Discover Top Techniques for Reliable Car Tool Cluster Repair and Upkeep

In the realm of auto maintenance, the detailed system of an instrument collection plays a vital role in providing vehicle drivers with vital details about their automobile's performance. When encountered with issues associated with this essential component, having a comprehensive understanding of effective repair work and upkeep strategies is paramount. From identifying common cluster malfunctions to using specialized tools for accuracy repairs, a methodical technique can make certain optimal functionality and long life of this vital dashboard feature. Keep tuned to uncover the top approaches that can simplify the process of auto instrument cluster repair work and upkeep, inevitably enhancing your driving experience and car performance.

Common Tool Collection Issues

Some usual problems may arise with vehicle instrument clusters, impacting their capability and accuracy. One common issue is a malfunctioning speedometer, which can result in safety issues and prospective legal issues otherwise resolved immediately. This problem commonly comes from a malfunctioning speed sensing unit or damaged circuitry, triggering inaccurate rate analyses or full failure of the speedometer. Another constant issue is a non-responsive fuel gauge, causing uncertainty concerning fuel degrees and potential unanticipated breakdowns. This trouble can be triggered by a faulty fuel level sensing unit or a malfunctioning scale collection. Furthermore, flickering or dim control panel lights are typical problems among vehicle owners. This issue may be associated to loose connections, a failing dimmer switch, or damaged bulbs. These issues can hinder the motorist's ability to keep an eye on important car details, emphasizing the relevance of prompt tool collection fixing and maintenance to make sure optimal functionality and accuracy while driving.

Essential Devices for Repair

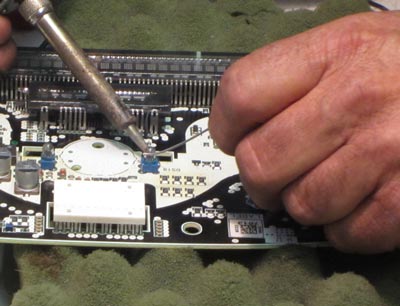

When dealing with usual tool cluster concerns such as malfunctioning speedometers, unresponsive gas gauges, or dim control panel lights, having the vital devices for fixing is critical in ensuring accurate and effective diagnostics and maintenance. Amongst the primary tools needed for vehicle tool cluster repair service are an electronic multimeter for screening voltage and resistance levels, a soldering iron for fixing malfunctioning elements or loosened links, and a set of screwdrivers for disassembling the collection. In addition, specialized tools like collection removal hooks may be needed for safely separating the cluster from the control panel.

Diagnostic Methods for Repairing

Making use of innovative analysis techniques is crucial in efficiently repairing issues within auto tool collections to pinpoint and attend to underlying issues precisely. By complying Visit This Link with methodical analysis procedures and translating diagnostic results properly, professionals can improve the troubleshooting procedure and guarantee the correct functioning of the tool collection. A detailed diagnostic approach not just conserves time but likewise advertises accuracy in determining and settling tool collection concerns without delay.

Cleansing and Maintenance Tips

Software Updates and Calibration

Calibration is one more important aspect of preserving your car tool collection. This process involves changing the settings and specifications within the software application to make certain that the displayed information, such as speed, fuel level, and temperature, is exact and reliable. Proper calibration not only boosts the customer experience yet additionally adds to safety on the road by providing drivers with specific and reputable information.

To make certain that your vehicle tool collection operates efficiently, it is suggested to comply with the producer's standards concerning software updates and calibration periods. By remaining positive in these areas, you can maximize the efficiency and life expectancy of your tool collection.

Final Thought

Finally, effective vehicle instrument cluster repair work and maintenance call for a comprehensive understanding of typical issues, important devices, analysis methods, cleaning techniques, and software application updates. By utilizing these strategies, service technicians can successfully troubleshoot and solve tool collection problems, site making certain precise and reliable performance of the lorry's dashboard display screen. Regular maintenance and calibration are vital to stop future issues and making certain the appropriate performance of the tool collection.

When addressing typical tool cluster concerns such as malfunctioning speedometers, unresponsive gas gauges, or dark control panel lights, having the necessary tools for repair service is essential in ensuring precise and efficient diagnostics and maintenance. Among the primary devices required for vehicle instrument cluster fixing are a digital multimeter for testing voltage and resistance degrees, a soldering iron for fixing loose links or faulty components, and a collection of screwdrivers for dismantling the cluster. In addition, specialized devices like collection removal hooks may be needed for securely removing the collection from the control panel.

In conclusion, effective automobile tool cluster repair service and upkeep call for a complete understanding of usual issues, important devices, analysis strategies, cleansing approaches, and software updates. Regular maintenance and calibration are essential to stopping future concerns and ensuring the proper functioning of the tool cluster.

Report this page